Our Foam

With more than 32 years of experience, PT SERIM INDONESIA has experienced various conditions and has grown into a company with integrity and is very concerned about the quality of each production, because we want every customer to get the best quality from our polyurethane foam.

FLAME RETARDANT FOAM

Flame Retardant Foam can fire ressistence by adding incombustible materials in PU foam. it is an ideal product for industrial usage. In order to add resistance to the fire, a layer of special chemicals is added to our foam products, which significantly reduces its chances of catching fire. Our Flame Retardant Foam is manufactured using imported machines, which makes sure that our foam products meet even the stringent international standards.

Applications :

- Insulation Part

- Sealing Parts

- Etc.

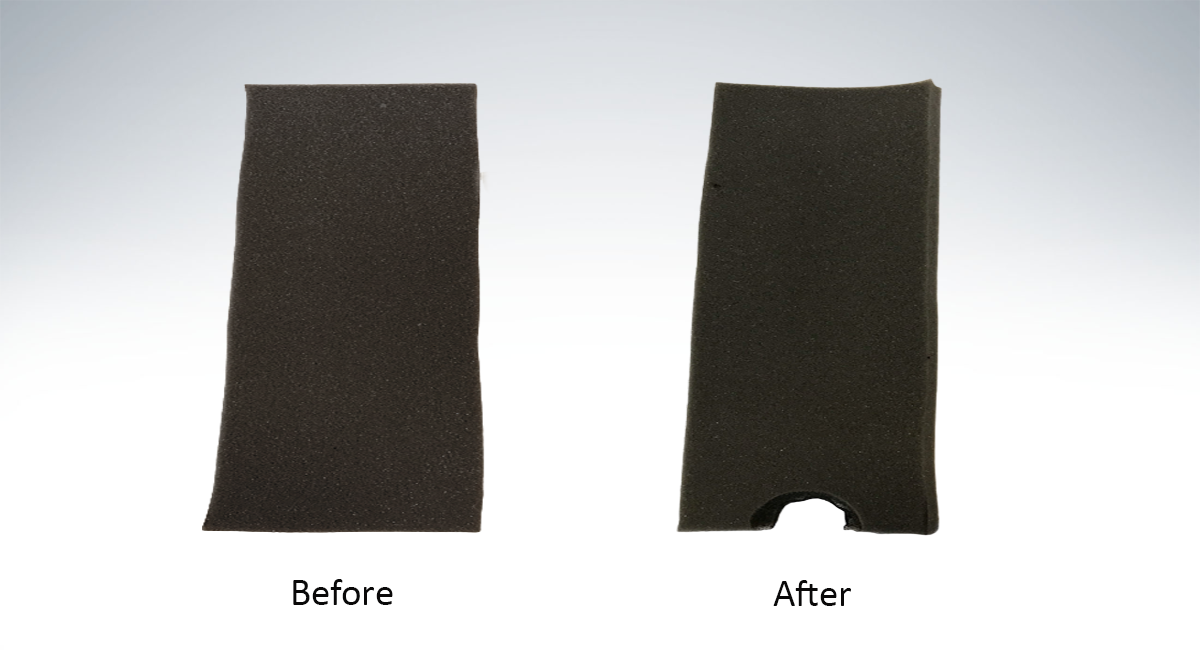

Flame Retardant Foam Test

Non-Flame Retardant Foam Test

Conslusion : With flame retardant foam the fire will go out quickly and burn only a small part of the foam. in contrast to ordinary foam then the fire will burn entirely.

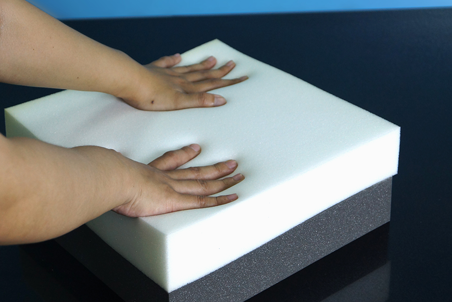

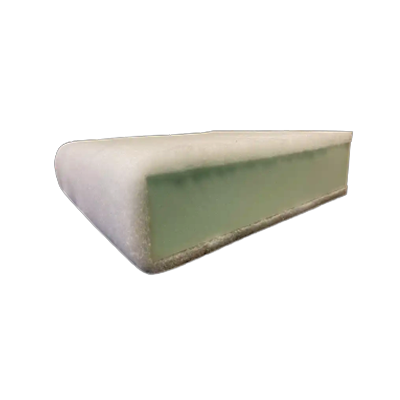

MEMORY FOAM

Memory Foam or Viscoelastic foam is a durable type of material, it is known for its high density, for providing good support and excellent pressure relief. This type of foam can conform to any pressure placed on it, thereby reducing strain on the body while supporting it with its strong resilience.

Applications :

- Pillows

- Bedding

- Shoe Pads

- Etc.

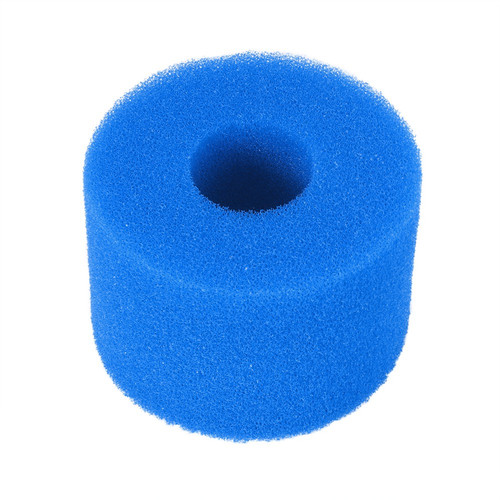

SFRESH FOAM

This foam is a versatile open-cell material that is lightweight, low odor and is highly resistant to mildew. This material family has strong chemical resistance, tensile strength, elongation, and anti-tear characteristics.

Applications :

- Water filtration

- Swimming Pool Cleaner

- Aquarium Filtration

- Etc.

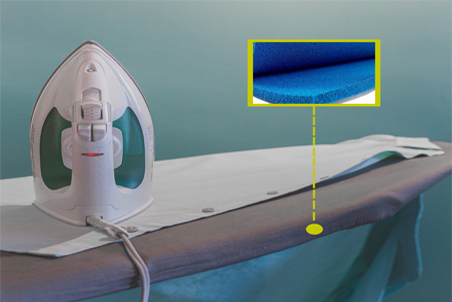

GENERAL FOAM

general foam designed to meet the needs of polyurethane foam in the market by prioritizing quality

Applications :

- Ironing Board

- Sofa

- Suitcase

- Dish Washing

- Etc.

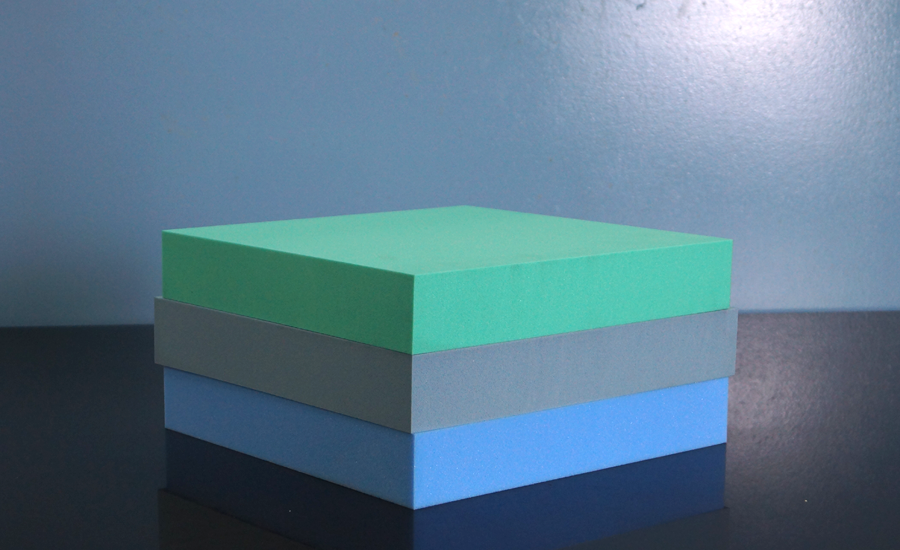

SMART FOAM

smart foam designed for extra comfort with excellent shock absorption with adjustable hardness. different from general foam type, this foam uses a different composition material

Applications :

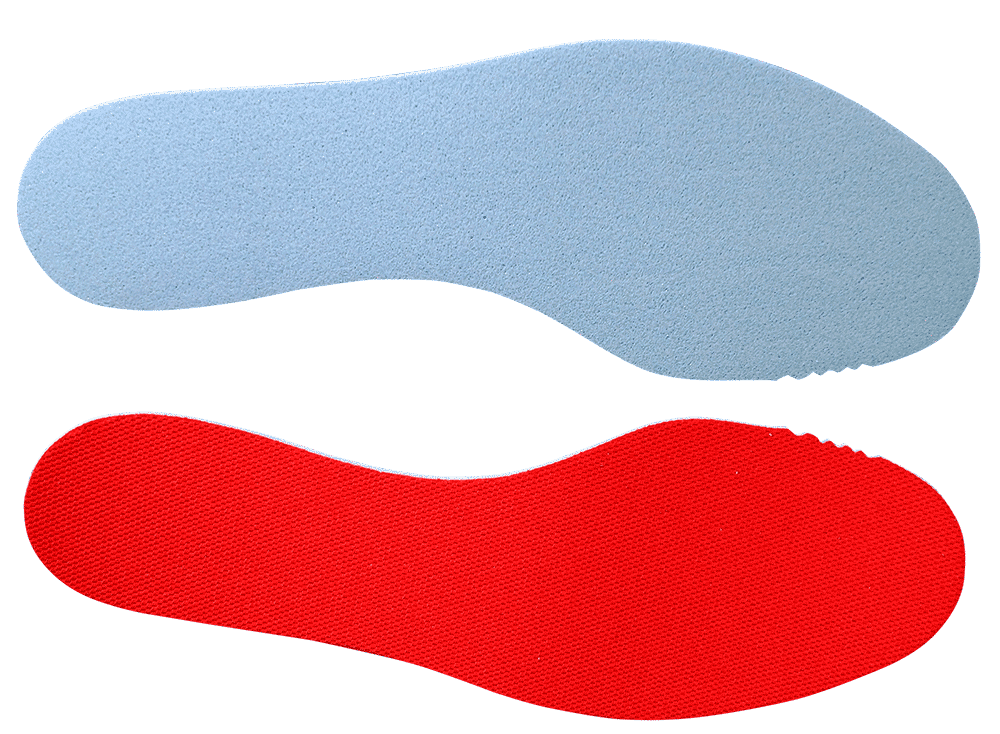

- Insole

- Etc.

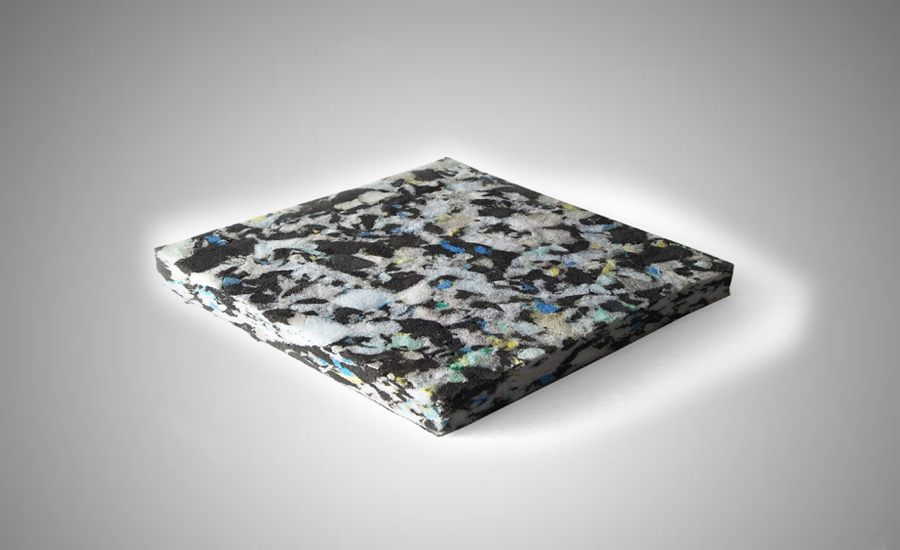

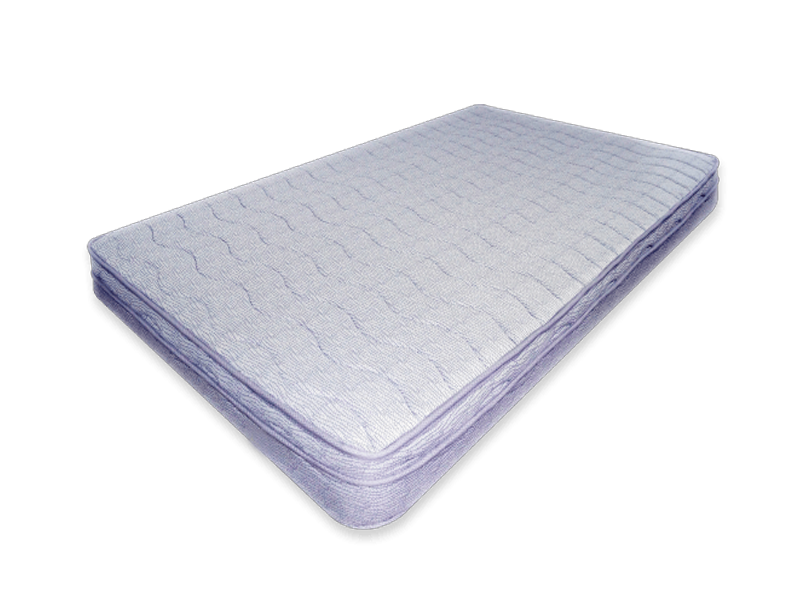

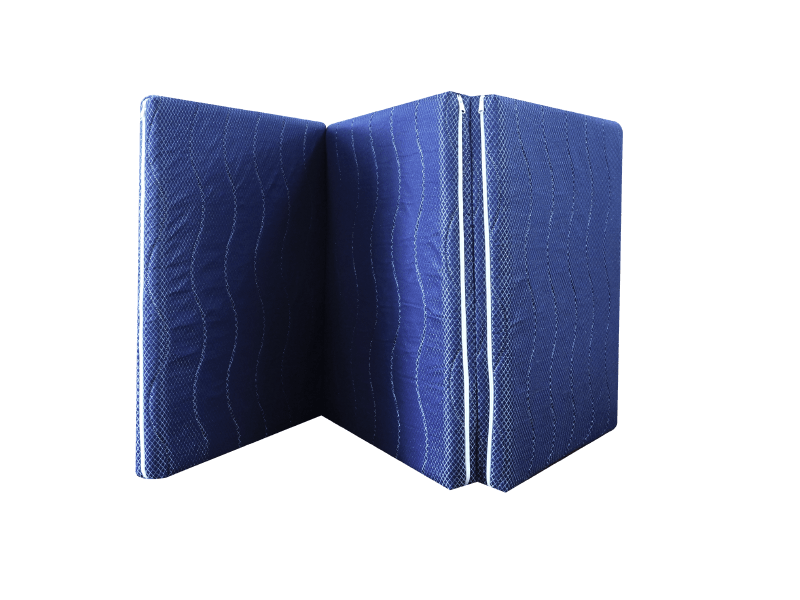

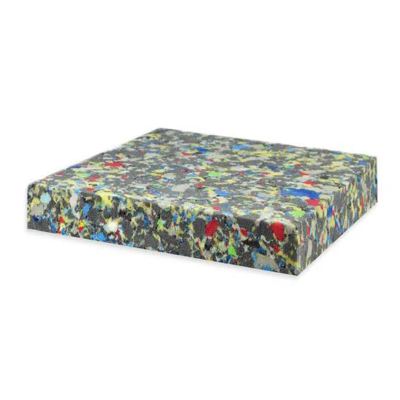

RECYCLE REBONDED FOAM

This foams are developed when foams of multiple densities are combined, broken down and re-bonded all over again, under mechanical pressure, as new blocks of high-density rebonded material. These are further cut, as per the desired length and width.

Applications :

- Insole

- Mattress

- Furniture

- Etc.

Business

We produce a wide range of products are required by various industries using Polyurethane Foam.

Shoe

Automotive

Mattress

Electronic

Garment

Furniture

Shoe

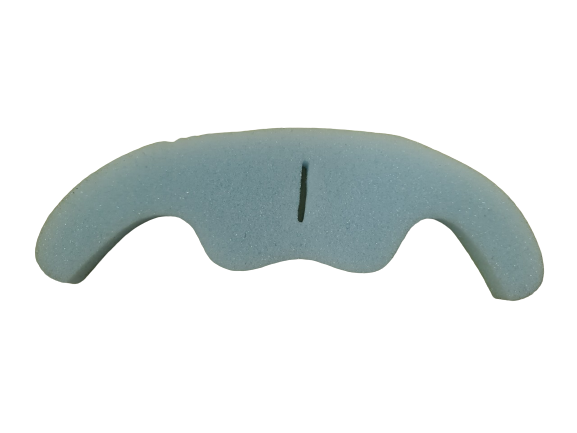

Tongue

Density : 16 - 60 Kg / M3

Collar Lining

Density : 20 - 80 Kg / M3

Upper

Density : 16 - 60 Kg / M3

Insole

Density : 60 - 180 Kg / M3

Click the cursor in the Shoe !!!

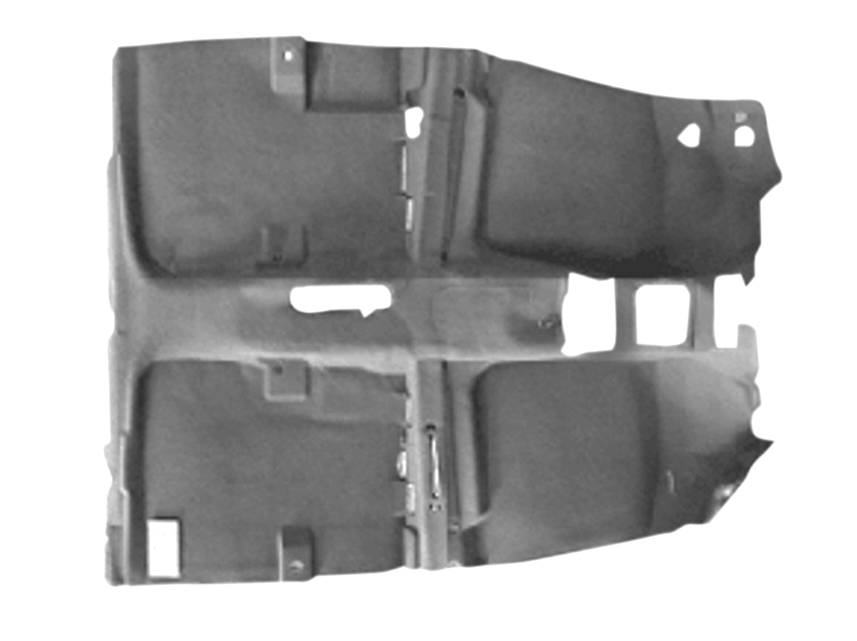

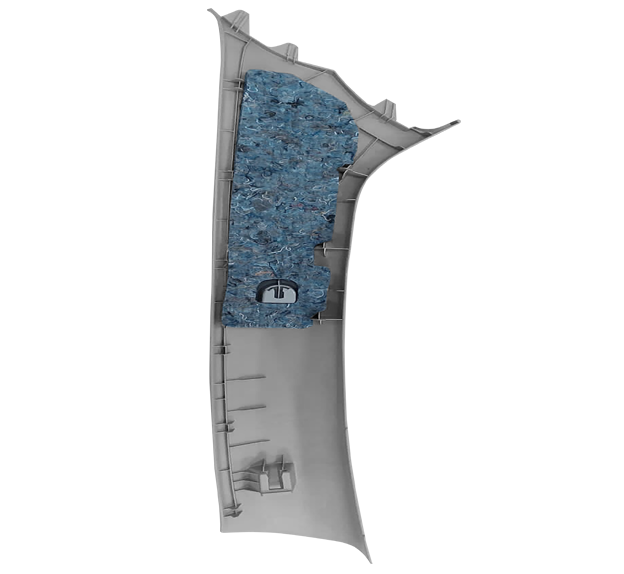

Automotive

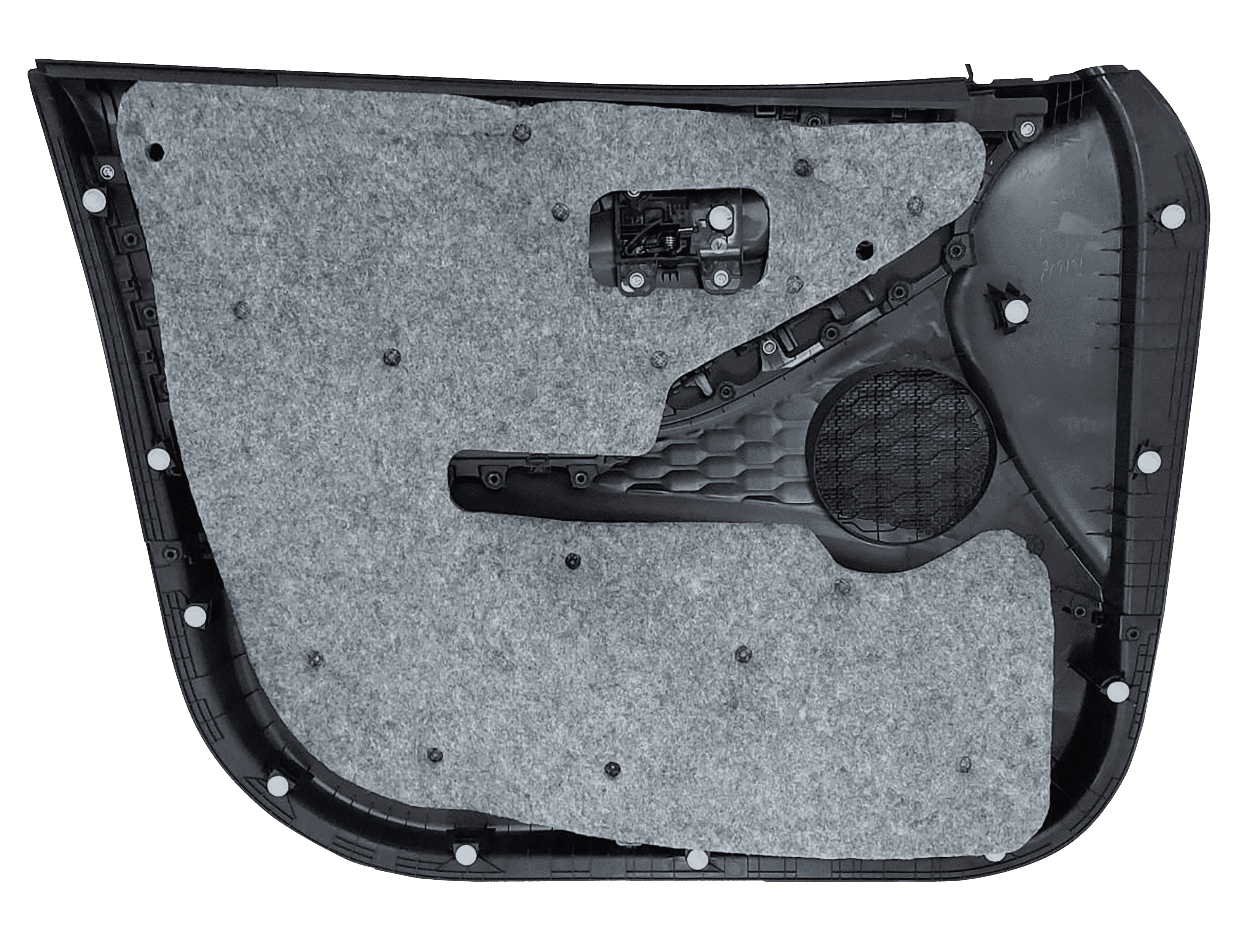

Door Trim

Protector Wheel House

Carpet Floor

Seat Cushion

Sunvisor

Dashboard

Pillar

Headliner

Click the cursor in the Car !!!

Mattress

Electronic

Prevention of condentation refrigerator

Speaker

Insulation Foam AC

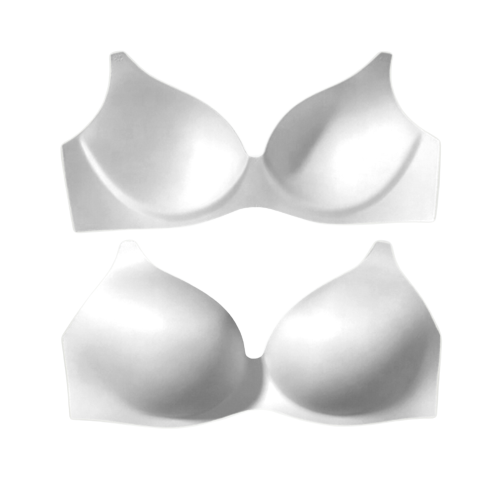

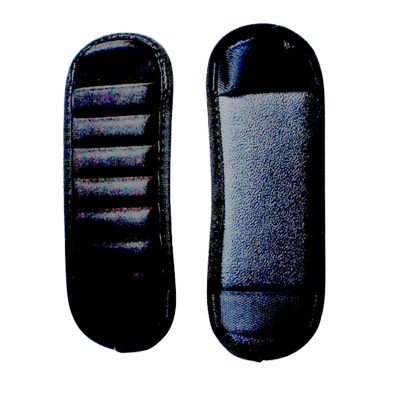

Garment

Mold Cup Bra

Shoulder Pad

Bag

Furniture

Chair

Sofa

Carpet Underlay

ETC

Sound absorbing foam at cinema

Filter foam at Swimming pool